Automotive Gears Car Gears Latest Price, Manufacturers & Suppliers

However, they also occur in conical, elliptical, square and triangular types. Circular gear techniques have a relentless gear ratio for rotary speed and torque. Therefore, related input produces the identical pace and torque output.

Gear producers are increasingly designing uneven gears, permitting larger loads with much less NVH. This introduces, on purpose, a defined and engineered “waviness†in the profile type deviation (commonly defined as ffα) and lead form deviation (commonly defined as ffβ). Yoders presented audio data in an interview with SME that dramatically demonstrated a gear with considerably less gear whine after NEO correction.

About The Firm

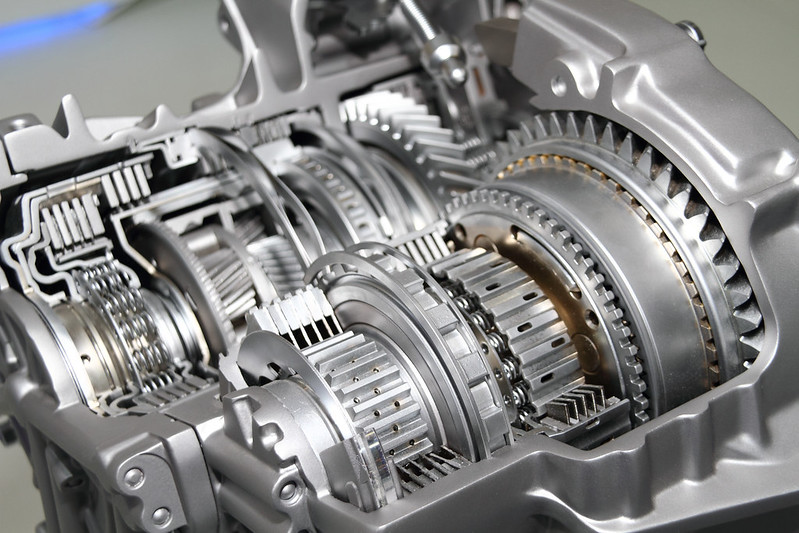

The design is a splitpower-path unit in which gear association is symmetrical and balanced across the axis. The resin and design additionally prevented the necessity for the counterweight sometimes found in other washer transmissions and eliminated the need for many secondary finishing operations. The new transmission had significantly fewer parts and was a lot lighter, making it simpler to assemble the unit manually. Encoders monitor the relative position of meshing gears underneath programmed loads to quantify backlash and indicate tooth stiffness, wear, and transmission error. The tester additionally defines a gear material’s fatigue energy by recording the number of cycles until enamel break at varied torques and temperatures. A rising choice for plastic gears is evident in the automotive business, where electrical techniques are eliminating hydraulics and cables in both inside and exterior purposes.

Although it may appear advantageous to make use of a straight minimize gear system, it’s not without its flaws. It’s necessary to note that it’s not the tooth themselves which are straight-sided but the forefront that runs parallel to the shaft’s axis. In this article, we’ll take a closer look at two of the commonest gear types and understand why one’s preferred over the other. Additionally, it’ll assist to match the professionals and cons of each gear design to ascertain the best choice for any given utility. We are the leading manufacturer of confirmed high quality gears, Shafts and other Engine and Transmission Components.

The market can be being pushed by the rising demand for lightweight automotive parts and fuel-efficient automobiles. Furthermore, due to their large processing capacities, entry to an abundance of uncooked supplies, and emphasis on raising profits by producers, China and Taiwan are important places for the production of gear. The largest automotive gears market is within the Asia-Pacific area, which can be predicted to develop at the quickest price over the following a quantity of years. Asia-Pacific is prone to dominate the automotive gears market, with China being a key contributor to the market’s progress.

Hypoid Gears

This downturn has slowed the growth of automotive products across all sectors over the past two years. Prolonged shutdowns in main manufacturing countries such because the United States, Germany, Italy, the UK, and China have disrupted manufacturing and tools gross sales. The closure’s potential long-term effects stay uncertain, posing challenges to monetary restoration and necessitating adjustments to investment plans. Manufacturers are always looking out for the right blend of efficiency and fuel financial system in every vehicle they launch, and determining the best gear ratio is a big a part of the process.

G. G. Automotive Gears Limited engages within the manufacture and sale of traction gears and pinions in India. GGAG isn’t just limited to safeguarding and defending the setting this contact form. As a responsible company, it additionally cares for its staff and the society collectively.

This is the place the black magic of automatic transmissions begins (we haven’t even gotten to planetary gears yet). One of the simplest and most used gear models, exterior gears are extensively used in gear pumps and different industrial merchandise for clean functioning. Precision gears are known for his or her bother free superior performance, lengthy service life, and excellent floor finish and customization functionality. These gears are utilized in a wide range of industrial purposes, corresponding to heavy equipment Industry, metallic casting, metal processing, construction, and more. As typically seen grinding is most of the time conceived in context of quantity fabrication of superior quality gears as a form of secondary refining procedure.